### Navigating the Impact of New Tariffs: Challenges for Businesses Relocating Production

In the landscape of international manufacturing, companies are continually adapting to changing economic climates. However, recent developments have introduced new challenges for businesses that have moved their production facilities from China to alternative destinations. The imposition of fresh tariffs has complicated this shift, causing significant disruptions and strategic paralysis.

### Why Businesses are Moving Out of China

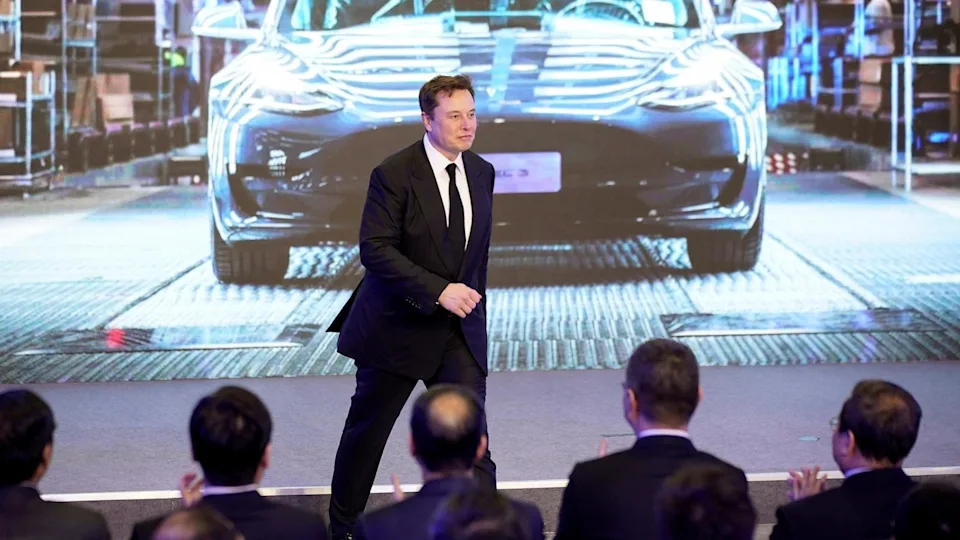

Over the past few years, a notable trend has emerged where businesses have been shifting their production bases away from China. This move has largely been motivated by a desire to diversify manufacturing locations and reduce reliance on a single country. Factors such as rising labor costs in China, political tensions, and previous tariffs have prompted businesses to look for manufacturing options in other countries that offer competitive costs and favorable business environments.

### The Unexpected Twist of New Tariffs

Just as many companies were settling into their new production havens, the introduction of new tariffs has thrown a wrench into the works. These tariffs have not only increased the cost of goods but have also left businesses scrambling to assess the feasibility of their newly established operations outside China. The companies that had anticipated a more stable and predictable business environment are now facing uncertainties that could affect their long-term strategies.

### The Effects on Business Strategies

The new tariffs have had a profound impact on the operational strategies of these businesses. For many, the shift out of China was seen as a strategic move to circumvent complications associated with geopolitical tensions and trade imbalances. However, the recent tariff changes have led to unexpected costs and challenges, forcing companies to reevaluate their global supply chains.

1. **Increased Costs**: The new tariffs have led to higher costs of importing goods into their target markets, particularly in the United States. This negates some of the cost benefits that were initially gained by moving production from China.

2. **Supply Chain Disruption**: Shifting production is no small feat and involves considerable logistical planning. The new tariffs have disrupted these carefully laid plans, causing delays and uncertainties in supply chain operations.

3. **Strategic Paralysis**: For some businesses, the unexpected shift in trade policy has caused a paralysis in decision-making. Companies are finding it difficult to plan for the future without a clear understanding of ongoing trade policies, which are critical to making informed business decisions.

### Moving Forward: Adaptation and Resilience

Businesses affected by the recent tariffs are navigating these challenges with a focus on adaptation and resilience. It’s becoming increasingly important for these companies to be agile and responsive to changes in the global economic environment. Here are a few strategies businesses are employing:

– **Exploring Alternative Markets**: Some businesses are looking beyond the traditional markets to mitigate the risk of future tariffs and are exploring opportunities in emerging markets.

– **Enhancing Local Production**: To cushion against import tariffs, some companies are investing in enhancing their production capacities within their target markets to reduce the dependency on imports.

– **Strategic Partnerships**: Forming strategic alliances can help companies share risks and resources, thereby reducing the impact of unexpected economic shifts like tariffs.

### Conclusion

The latest round of tariffs has certainly brought to light the challenges of global manufacturing and trade. While businesses endeavor to adapt to these new hurdles, the situation underscores the importance of strategic foresight in business planning. Companies must continue to assess their supply chain strategies and remain flexible in their approach to overcome the challenges presented by the ever-evolving global trade landscape.